the Environmental benefits of deconstruction

The many eco-friendly (and economic!) benefits of deconstruction, the sustainable alternative to demolition

With more than 8 billion people on the planet and limited natural resources, creating systems that sustainably manage our waste and help regenerate natural systems is more important than ever, especially for the construction and demolition industry: Globally, the construction industry uses half of the 100 billion tons of material extracted from nature every year, and is responsible for a third of the world's waste and 40% of carbon dioxide emissions.

Here in Colorado, C&D waste makes up one-third of all our landfills. Thankfully, many communities are beginning to take action: Denver, Boulder, Lakewood, and Pitkin County have all implemented policies or requirements to help divert reusable and recyclable material from landfill.

Did you know?

Founder Anna Perks participates as an advisor on deconstruction efforts throughout the state available to help municipalities and contractors with waste and reuse plans, diversion reports, trainings and more.

Need advice for your community or a presentation for a group? reach out at anna@perksdeconstruction.com

A more sustainable way forward

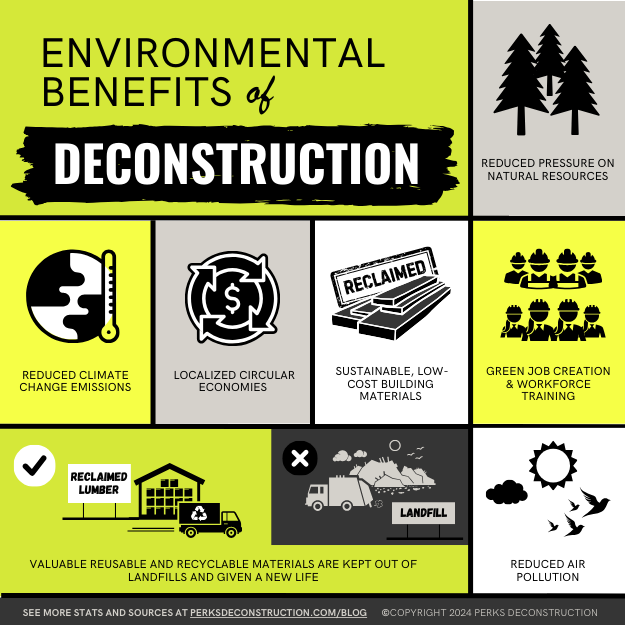

There is a way to tackle this incredible mass of waste from the construction industry, and it’s called deconstruction. The obvious benefits of deconstruction – the disassembly of homes and buildings to recover as many materials as possible – include the fact that many building materials get reused and recycled. This means fewer building materials end up in a landfill, and that they get put to good use instead.

But beyond landfill diversion, deconstruction practices help create a world and cycle that help regenerate resources (by reusing lumber instead of harvesting trees) and create circular economies (by creating Zero Waste systems). These cycles are built on principles that prioritize good design, reuse and recycle materials whenever possible, and generate low-to-no waste or pollution. Our vision for the construction and demolition industry is one where deconstruction practices are prioritized and reclaimed lumber becomes a standard and widespread practice.

Here’s are all the benefits that come from adopting deconstruction practices for your home or business instead of going the conventional route of demolition.

Deconstruction practices reduce our dependence on finite natural resources

When we deconstruct a home or office, we’re carefully salvaging reusable building materials to be reused in other projects or, sometimes, upcycled into new products. This salvage and reclaim process creates a market of sustainable building materials that are also sourced locally, creating an overall smaller carbon footprint and providing an alternative to virgin lumber harvested from trees. The more we choose deconstruction, the more we can grow these sustainable lumber markets and lessen the pressure we put on our forests.

Deconstruction provides affordable and sustainable building materials to the public

When you buy reclaimed materials, you’re not only supporting a “Share Economy” of second-hand goods; you’re also preventing waste. Take for instance lumber: By purchasing reclaimed wood over virgin wood, you are preventing all the carbon emissions, pollution, energy use, and other negative impacts of extracting and producing lumber from natural resources – trees. When you purchase reclaimed, you’re avoiding the natural-resource-to-landfill process entirely and instead extending the life of a product that would have otherwise been trashed. It’s practically a net-positive impact: Instead of supporting a wasteful process, you’re creating new opportunities for otherwise trashed materials. As an added bonus, because they haven’t been through the typical manufacturing processes as new materials, reclaimed building materials come at an overall lower cost over big box stores, making reclaimed building materials a sustainable and equitable resource for communities.

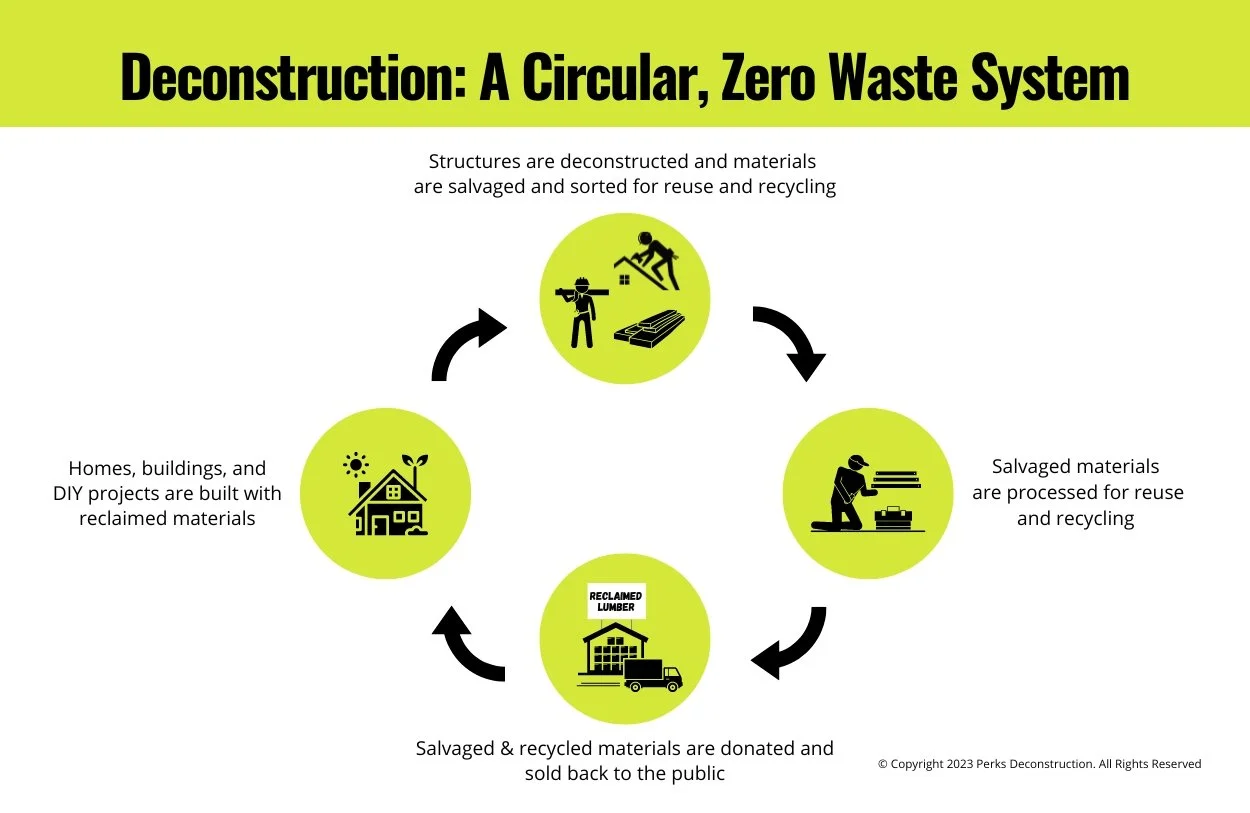

Deconstruction supports a circular economy

Right now, virgin lumber is the overwhelming choice for new construction projects, and the materials go overwhelmingly one way: From being extracted from the earth to being wasted in a landfill. This follows a take-make-waste system that exploits our resources and doesn’t account for pollution and carbon emissions in its true cost.

On the other hand, deconstruction is a circular, Zero Waste loop: Materials are removed from structures and reused in future projects, a cycle that can be repeated to eliminate the need for new materials as well as waste. These Zero Waste systems minimize the need for raw resources and the energy used to turn them into products.

Deconstruction follows the 3 principles of a circular economy:

REDUCTION OR ELIMINATION OF WASTE AND POLLUTION

EXTENSION & CIRCULATION OF PRODUCTS AND MATERIALS AT THEIR HIGHEST VALUE

REGENERATING NATURAL SYSTEMS

Learn more on our blog post, Deconstruction and the Circular Economy.

Deconstruction fights climate change by keeping biodegradable materials out of the landfill

Biodegradable materials like wood and other natural products create greenhouse gasses when buried in a landfill. These materials do not break down like they would in natural or compost environments, which provide air to materials as they break down. Rather, in a landfill, biodegradable materials break down without oxygen, creating methane, a potent greenhouse gas that contributes to climate change. When we prevent wood and other biodegradable and compostable materials from entering a landfill, we prevent these methane emissions, creating a more sustainable path for biodegradable demolition materials and doing our part to curb climate emissions.

Deconstruction creates green jobs

Unlike demolition, which relies on wrecking balls and other large machinery to destroy and trash structures expeditiously, deconstruction takes a more methodical, almost surgical approach to disassembling structures. This process requires a skilled team that can identify materials for reuse and recycling and carefully remove materials piece by piece, preserving their value and working with other entities to create and establish markets for materials. These practices create additional jobs in the green construction and demolition (C&D) sector and provide green workforce training to those interested in the field. In 2018 alone, the deconstruction industry in the U.S. accounted for 14,500 jobs.

Deconstruction reduces air pollution and disruption to local environments

Because deconstruction teams disassemble structures instead of wrecking them, the result is a cleaner and less polluting process. Dust clouds and debris are minimized during the deconstruction process, reducing the amount of particles landing in the environment around the home or building. Noise pollution is also minimized, as well as air pollution.

Pictured: A near-complete house deconstruction project. Deconstruction is a great choice for those looking to minimize local dust, debris, and pollution during their home renovation projects.

Boulder & Denver AREA FOLKS: Contact us with your home or business demolition needs!

We are a mission-driven company that always prioritizes salvaging as many materials as possible from our deconstruction and demolition jobs. Give us a call today about your home or business renovation – we’ll help make the process smooth, easy, and something you can feel good about!